Solid-state materials science

Preparation of dielectric materials:

We prepare variety of dielectric (mainly ferroelectric, multiferroic and piezoelectric) materials in forms of ceramics, (nano)powders, nanoparticles, nanosuspensions, films, (nano)composites and single crystals. The techniques used are solid state synthesis (possibly using mechanochemical activation), hydrothermal and solvothermal synthesis, sol-gel technique, combined sol-gel-solvothermal synthesis and crystal growth from solution.

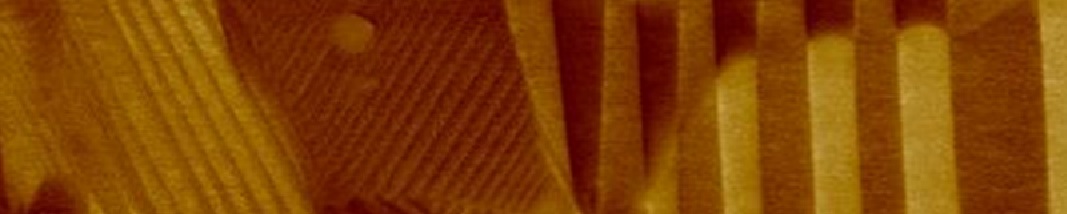

Figure:

BaTiO3 film with pseudocubic grains hydrothermaly

deposited on Ti substrate -

development of electrically active

coatings for bone implants.

The ceramics are prepared by uniaxial pressing followed by pressureless sintering. We can modify the properties of powders and ceramics by annealing in various gases as oxygen, argon, argon-hydrogen, and pure hydrogen. Thin films are deposited by hydrothermal technique and spin coating. Soft chemistry technology has been used for filling nanoporous materials with ferroelectrics.

Examples of prepared materials:

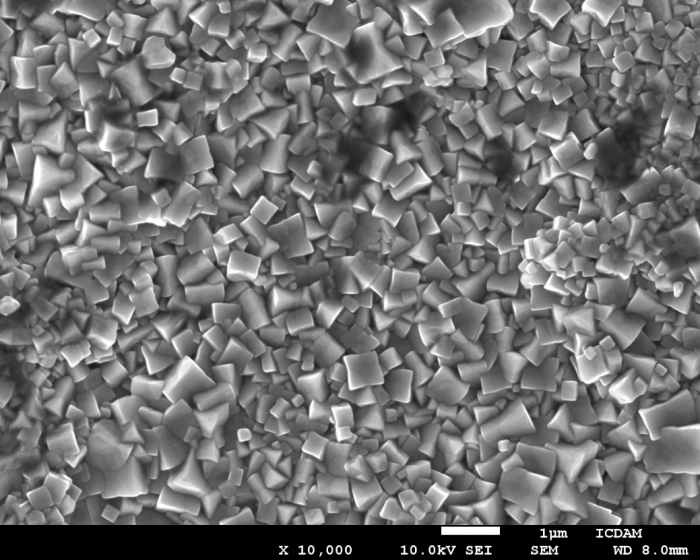

- multiferroic EuTiO3, Eu0.5Ba0.5TiO3, Eu0.5Ba0.25Sr0.25TiO3, CaMn7O12 and SrMn7O12 in the form of powders and ceramics, ferroelectric BaTiO3 nanoparticles for doping liquid crystals, biocompatible ferroelectric BaTiO3 films deposited on Ti and TiNb substrates (with perspective application for electrically active bone implants), series of relaxor ferroelectric SrxBa1-xNb2O6 with various Sr/Ba ratio, multiferroic lacunar spinels GaV4S8 (powder and ceramics) and GaV4Se8 (powder) possessing skyrmion phase. We optimize the solid-state synthesis of multiferroic BaCuF4. Some samples for spectroscopic measurements are prepared by etching an thinning.

-

Gold nanoparticles are prepared by the reduction of HAuCl4, we test the deposition of these nanoparticles on AFM tips for the use in tip enhanced Raman spectroscopy (TERS). Crystal growth from solution has been used for the system of PbCa2(propionate)6, SrCa2(propionate)6 and BaCa2(propionate)6 as well as for the related substituted compounds by Mg (skyrmion investigation), single crystals of (NH4)3H(SeO4)2 and (NH4)3H(SO4)2 for diffuse scattering experiments.

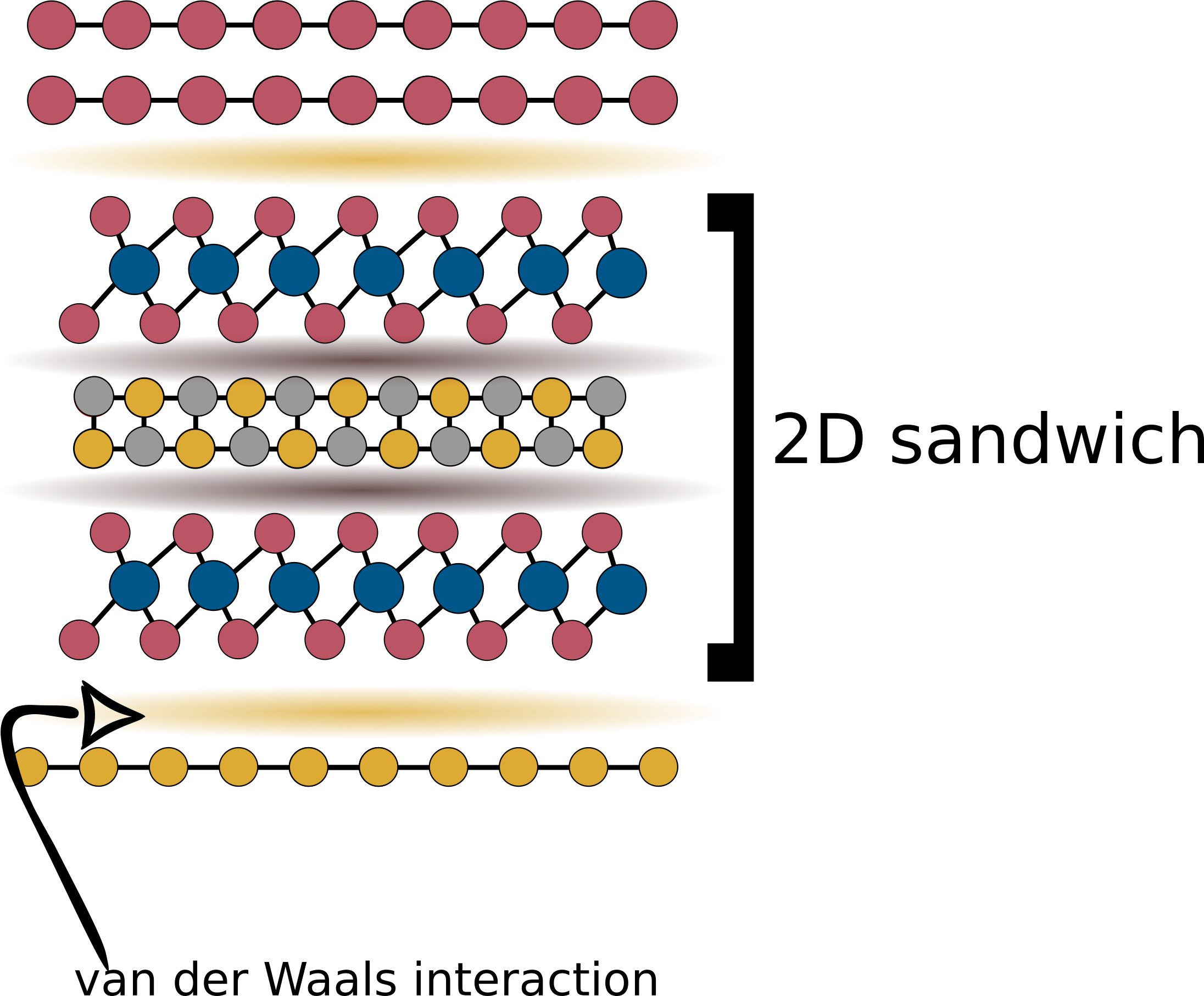

Growth of 2D sandwiches, artificial layered building blocks for multifunctional materials:

Our ERC Starting Grant funded line of research focuses on the creation of a new two-dimensional (2D) building block: the 2D sandwich. This is a layered heterostructure, consisting of a mix of layered van der Waals, layered ionic and layered metavalent materials. In the 2D sandwich, an interaction between the sandwich's individual layers is mediated via an ionic or multivalent bond (gray cloud between the layers in the picture), whereas the interaction with other 2D layers is still solely due to the van der Waals interactions (yellow cloud between the layers in the picture). There are still many open, fundamental questions concerning the creation of 2D sandwiches. We explore design strategies to create such heterostructures and try to answer if and how materials with a van der Waals bond can be combined with layered ionic and layered metavalent materials. The ultimate aim of the project is to create a 2D sandwich, which will be multiferroic working at ambient conditions.

2D magnetoelectric multiferroic sandwiches composed of layered transition metal chalcogenides, oxides or iodides will be grown using the modulated elemental reactants method. Using a combination of X-ray diffraction, electron microscopy and optical spectroscopy, we will explore their structure and properties and try to answer fundamental questions if and how materials with a van der Waals bond can be combined with layered ionic and layered metavalent materials and how the interaction between them might result in multiferroicity.

Characterization of prepared materials:

We look for structural phase transitions and determine their basic thermodynamic data (temperature, enthalpy change, entropy change) in the prepared materials by differential scanning calorimetry (DSC). The phase composition, structural data and crystallite dimensions are determined by X-ray diffraction, partially in collaboration with the Department of Material Analysis. Some single crystals are characterized by X-ray single crystals diffraction in cooperation with the Department of Structure Analysis. We use also scanning electron microscope in the Department of Material Analysis. We look for and determine nonlinear optic properties. Raman spectroscopy is used in collaboration with the research group of dielectric and IR spectroscopy.

We characterized electrical activity of ferroelectric biomaterials immersed in the solution by the measurement of zeta potential at solid-liquid interface.